SmartDFE™ for Labels and Packaging is an award-winning collection of innovative and market-proven components that enable your engineering team to get to market quickly whilst giving them the space and capability to add their own value. SmartDFE is a full software stack for high-speed, single-pass, label and packaging inkjet presses. It includes everything from job creation and pre-press workflow through to printhead drive electronics. SmartDFE includes print intelligence, giving you industry-leading quality without the PhD and secure connectivity to power Industry 4.0 scenarios.

Read more

Case studies

White papers

- Choosing a digital front end for your high-speed, single-pass, roll-to-roll inkjet press

- Optimizing digital watermarking in print workflows

Brochures

Datasheets

Videos

Documentation

Tools

Partners

Features and benefits

Smart Workflow and Prepress Tools

- Smart Job Cost Estimator

- Equip your customer's sales team with the most accurate job estimation software

- STEPZ® (Optional)

- All-in-one solution for prepress and VDP – based on PDF

- Designed for Labels & Packaging

- Full, brandable front end

- Optimized PDF creation for on-the-fly printing at full speed

- Define templates for dynamic document design

- Export die cut for toolmaking

- Smart Workflow

- Connect to the business, transform customer requirements into press-ready PDFs

- Advanced label and packaging workflow built using HYBRID Software's CLOUDFLOW®

- Designed for Labels & Packaging

- Support for Management Information Systems (MIS)

- Advanced workflow designer

- Variable data expansion

- Multiple printer control

- Cloud front end

Smart Control

- Drive your press at maximum speed with your own brandable inline RIP controller

- Press Operator's controller

- Full, brandable front end

- Harlequin Direct at Heart: designed to drive the fastest, widest and highest resolution inkjet devices

- Full variable data streamed directly to the device electronics

- Instant printing, no need to RIP ahead

- Easily scalable with extended gamut and special colors

Smart Performance

- Boost productivity using AI-based RIP tuning

- Patented Streamline Estimate™ technology estimates achievable line speed before committing to run a job, saving waste and making inline ripping a true production capability

- Simple traffic light system lets the operator know the job can be run at press speed

- Patented Streamline Autotune™ technology optimizes and intelligently configures the system for each job, achieving maximum levels of productivity

- Convert formats to streamlined PDF including (eg IJPDS and PPML)

Smart Connectivity

- Integrate into your own front end and connect to Industry 4.0 (OPC UA)

- Create or integrate using most development languages

- Integrate into the wider factory and SCADA systems

- Connect securely to the Cloud and remote monitoring systems

Smart Quality

- Enable your customer's press operators to achieve the best quality without the need for a print specialist

- Create a library of predefined media definitions describing all the settings needed for perfect color and quality

- Supercharged by ScreenPro™ with advanced inkjet-specific screens and custom screen design service

- Powered by the award-winning PrintFlat™ technology, taking inkjet quality to the next level

- Enhanced with industry-leading color tools with ColorLogic Inside

SmartQI

- Stream data directly to industry-standard inline quality inspection systems

- Areas of interest highlighted (eg labels, variable data)

- Generates color-managed RGB raster data for every page

Printhead Drive Electronics

- SmartDFE can support any printhead drive electronics and file types (eg PRT or TIFF)

- Meteor Printhead Electronics are supported out of the box

- Powerful printhead-independent drive electronics

- Choose the right inkjet printheads for your application

- Mix printhead models within the same press

- Change your mind about inkjet printheads with minimal risk

- Simulate output before you are ready - saving ink, media and production time

Smart Workflow and Prepress Tools

Transform customer requirements into press-ready PDFs

Smart Workflow is a comprehensive solution that optimizes and automates labels and packaging workflows, enhancing inkjet press productivity. Our expert team uses STEPZ and CLOUDFLOW from HYBRID Software to create customized workflows that seamlessly integrate with SmartDFE. We also collaborate with HYBRID Software's services groups to integrate workflows with MIS and ERP systems at your customers' locations, resulting in improved production processes, operational efficiency, and customer satisfaction.

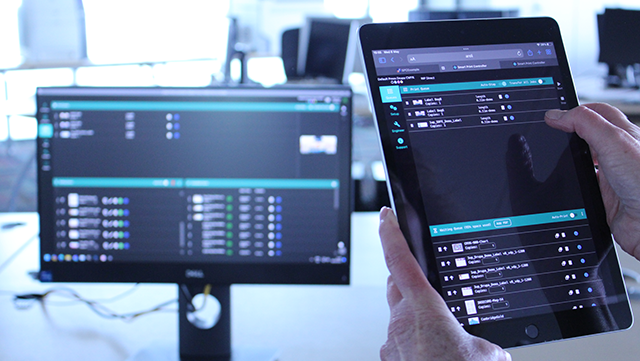

Smart Control

Your own brandable inline RIP controller

Experience the power of a fully customizable Digital Front End (DFE) that adapts to your brand requirements. This solution provides a seamless entry into the market, enabling swift integration. Operating in server (headless) mode, it also effortlessly complements your existing front end setup. Seamlessly integrate with Smart Print Controller (SPC) through the OPC UA API, enhancing connectivity.

Smart Performance

Boost productivity using AI-based RIP tuning

In the printing industry, even pages that look the same can take different amounts of time to process, which can be a problem. Our Streamline Autotune AI technology helps predict how long a job will take to RIP. It gives operators a clear signal - green means it's safe to print, amber means be cautious, and red means there might be problems. Autotune also enhances performance automatically by adjusting jobs and RIP processes, leveraging our dual ownership of the RIP and PDF analysis technology.

Smart Connectivity

Connect SPC to existing UI or craft new ones

SmartDFE enables secure communication within printing presses, factories, and the Cloud. It enables Original Equipment Manufacturers (OEMs) to quickly market products using standard press controllers or custom front ends that integrate with existing systems. At its core, the Smart Connectivity layer, powered by OPC UA, ensures robust and secure interactions with devices and applications in the press, Cloud and on mobile, supporting features like remote monitoring and predictive maintenance. SmartDFE incorporates print communication standards (JDF and JMF) for enhanced interoperability and efficiency in print production workflows.

Smart Quality

Achieve top-quality output without the need for a PhD

In today's printing landscape, achieving top-quality prints and precise colors often relies on skilled print operators. However, there's a shortage of these experts. This is especially noticeable in industries integrating print into broader processes, where non-specialists take on printing tasks. To address this, Smart Quality combines advanced technologies like PrintFlat, ScreenPro, and ColorLogic into a user-friendly system, making it easier for any operator to achieve excellent print quality.

SmartQI™

Synchronize SmartDFE with advanced vision systems

Incorporating an additional RIP Server PC into your system establishes a direct link with a vision system for quality assessment using SmartQI™. This server is adept at delivering RGB composite images to your inspection system, ensuring they are in sync with the rasters sent to the press. Such synchronization is crucial for uniform control of both the printing and inspection processes.

Universal support for printhead drive electronics

SmartDFE works with any printhead drive electronics and supports various file types like PRT and TIFF. Quick support for new electronics or formats is often available within weeks through a BreakThrough project. It’s already compatible with printhead drive electronics from Meteor Inkjet, known for its wide support in industrial inkjet printing. This allows easy integration of different printheads, even from various manufacturers, in one press. Additionally, Meteor Inkjet offers comprehensive tools and services to ensure high product performance and efficient workflows.

Streamline your SmartDFE solution with a single supplier

Our approach combines the convenience of a single supplier for SmartDFE components with the flexibility to choose different options, supported by our 30 years in printing. We use open standards like OPC UA for better compatibility. Committed to innovation, we offer key components as SDKs, allowing customization to meet your unique market needs.

Accelerate to market with our free BreakThrough service

Our business model, centered on partnering with you, offers SmartDFE licenses linked to your printer sales, starting when your product is ready for the market. Our objective is to help you launch quickly. Our BreakThrough service adds our expert engineers and scientists to your team, accelerating your product's market launch. You can buy this service in blocks of days, and the cost will be balanced against SmartDFE licenses once your press ships, effectively making it free. This service is part of our commitment to your success, aiming to reduce challenges and speed up your market entry, benefiting both of us.

SmartDFE editions

SmartDFE is available in various editions, each featuring a unique blend of Hybrid Software Group components.

|

|

|

|---|---|---|

| Smart Control (including Harlequin Direct™) | ||

| Smart Quality™ | ||

| ColorLogic Inside | ||

| PrintFlat™ | ||

| Smart Connectivity™ | ||

| Smart Performance™ | ||

| SmartQI™ | ||

| Meteor Ready™ | ||

| Smart Job Cost Estimator™ | ||

| CoPrA™ and ColorAnt™ | ||

| STEPZ® | ||

| Smart Workflow™ |

Variants

There are four variants of SmartDFE with different hardware requirements and price points. The lowest variant is "Static"; this is recommended where the press is only going to print many copies of a static design ie a single piece of content printing many times. The top variant is Ultra High Data Rate (UHDR), which is designed to produce the huge amounts of data generated by fully variable data on the fastest, highest resolution, widest and best quality inkjet printing presses. Calculate which variant you need using the Data Rate Calculator.

| Variants | Abbreviation | Example Data Rate | Description |

|---|---|---|---|

| Static | Static | NA | A single PC running all the software and generating a static raster which will be printed many times. |

| Standard Data Rate | SDR | Up to 3GB/s | Typically, two PCs, one running Harlequin Direct and other the workflow and controller software. Designed for less demanding variable data, lower resolution, narrower and lower speed presses. |

| High Data Rate | HDR |

Between 3GB/s and 18 GB/s |

Typically, more than one PC running Harlequin Direct and another running the workflow and controller software. Designed for most common variable data and main stream press capabilities. |

| Ultra High Data Rate | UHDR | Above 18 GB/s | Typically multiple state-of-the-art PCs driving Harlequin Direct. Designed to produce the huge amounts of data generated by fully variable data on the fastest, highest resolution, widest and best quality inkjet printing presses. |

If you're integrating SmartDFE into your own workflows or solutions, you can expand your experience and expertise by calling on one of our partners. The SmartDFE Partner Network includes experts in enhancing connectivity, performance, quality and workflow.